Case Studies in Brasilien

ALBANESI

ALBANESI

Branch in charge: São Paulo, SP, Brazil

Destination: Campinas, SP, Brazil

Cargo:

3 Turbines to Albanesi Project, Argentina

2 x 100 ton + 1 x 155 ton single weight

Volume: 514,76 frt / 355 ton

FPSO BUZIOS V PROJECT (GTCS)

FPSO BUZIOS V PROJECT (GTCS)

Branch in charge: São Paulo, SP, Brazil

Destination: Port of Santos, SP, Brazil

Cargo:

02 x GTCs (Turbogenerators)

Each loaded on: 02 x Heavy Prime Movers 6x4T + 22 Axle Line + Platform with total dims (cargo + truck set): L 75,00 x W 6,20 x H 5,90 m

Volume: 200 ton x 2 / about 1.303,00 FRT (ttl)

Job description:

- Development of Special devices to load heavy cargoes without necessity of using Girder Bridge;

- Special Devices manufacturing;

- Engineering service (own team / staff);

- Precarriage from Santa Barbara D’Oeste, SP, Brazil up to Port of Santos, Brazil;

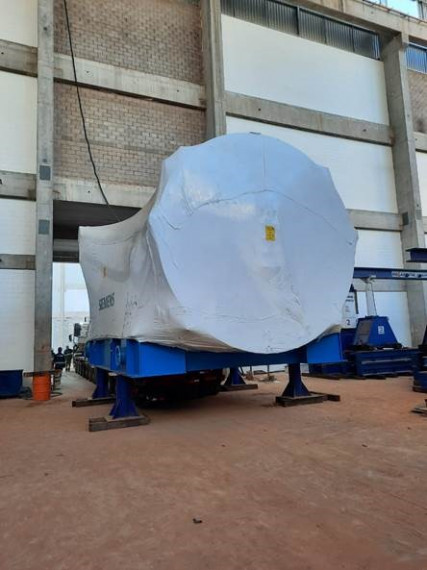

FPSO BUZIOS V PROJECT (GTGS)

FPSO BUZIOS V PROJECT (GTGS)

Branch in charge: São Paulo, SP, Brazil

Destination: Port of Santos, SP, Brazil

Cargo:

04 x GTGs (Turbogenerators)

Each loaded on: 02 x Heavy Prime Movers 8x4T + 16 Axle Line with hydraulic neck

Volume: 145 ton x 4 / about 1.434,00 FRT (ttl)

Job description:

- Engineering service (own team / staff);

- Precarriage from Santa Barbara D’Oeste, SP, Brazil up to Port of Santos, Brazil

BRACELL PROJECT 1

BRACELL PROJECT 1

Branch in charge: São Paulo, SP, Brazil

Destination: Lençóis Paulista, SP, Brazil (Bracell’s Pulp & Paper site)

Cargo: 02 x Complete set of Turbogenerators

Volume: 03 x Turbines (1 x 160 ton + 1 x 194 ton + 1 x 200 ton) 03 x Generators (GW 155 ton each) + Loose cargoes (about 1.570,00 ton)

Job description:

- Loading turbines at Jundiai and moving it, using 18 up to 24 axle lines, till Bracell’s site

- Receiving generators (under hook), using a 16 axle line, at Port of Santos and moving it up to Bracell’s site;

- Discharge operation of all heavy units using gantry cranes onto pad at Bracell’s site;

- Engineering service (own team / staff);

- All carriages from Port of Santos or Jundiai up to Bracell’s site for all loose items, including SOC containers;

BRACELL PROJECT 2

BRACELL PROJECT 2

Branch in charge: São Paulo, SP, Brazil

Destination: Lençóis Paulista, SP, Brazil (Bracell’s Pulp & Paper site)

Cargo: Condensers

Volume: 02 x Condensers (each with dims: L 11,75 x W 4,77 x H 4,20 m / GW each: about 42 ton)

Job description:

- Discharge operation using 02 Cranes In Tandem;

- Engineering service (own team / staff);