THE EXPERTS FOR

HEAVY HAUL & RIGGING

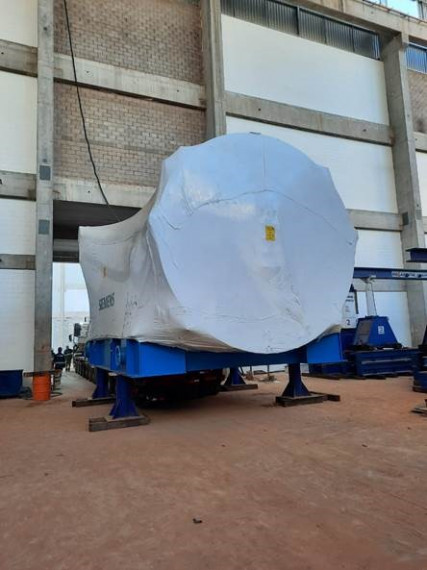

We offer you customized transport and rigging solutions for heavyweight and special transports.

Hansa Meyer offers licensed inhouse Transport Engineering and a dedicated longtime partner network with State -of – the Art Transport and Rigging Equipment such as SPMT s, low bed trailers, gantries, lifting and skidding devices.

Our selected global partner network maintains an extensive vehicle pool with own state-of-the-art equipment.

Our technical Services do include

- transport studies

- route surveys

- engineering services

- static calculations

- loading supervisions

- designing and construction of transport racks and devices

- De- and recommissioning of complete plants