Case Studies in South Africa

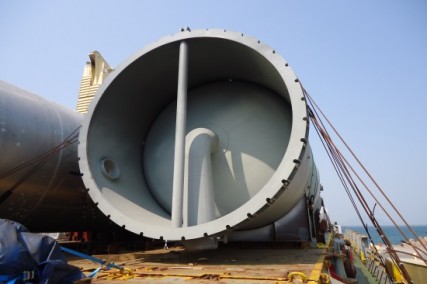

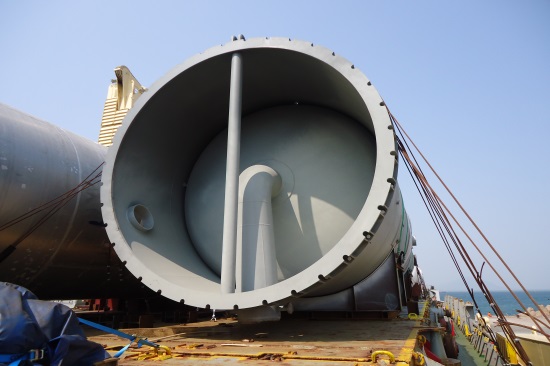

Hydropower Station

Hydropower Station

Branch in charge: Germany

Destination: Ladysmith via Durban, South Africa

Cargo: Hydropower Station

Volume: 145,150 frt

Job description:

One MIV (valve) U3 was loaded on rail at Voith York (USA) in cooperation with HMGT Houston to be shipped via Savannah to Durban, ZA.

Shipment over 145 t was handled by a coastal crane on both sides.

In Durban, the MIV was discharged on a SPMT trailer and then placed on the elephant feet until the trailer for onward transportation was available.

Air Separation Plant

Air Separation Plant

Branch in charge: Germany

Destination: Pretoria West, South Africa

Cargo: Air Separation Plant

Volume: 3,000 frt

Job description:

A turnkey plant was shipped by us, consisting of a 200-t/d GOX 6000 air separation unit, an Argon rectification column and respective equipment.

The largest item was approximately 4 x 4 x 20 m, max. item weight – 25 t.

Mining Equipment

Mining Equipment

Branch in charge: Germany

Destination: Durban and Richards Bay, South Africa

Cargo: Mining Equipment

Volume: 3,686 frt

Job description:

The cargo was loaded in Shanghai, China, and shipped to Durban and Richards Bay, South Africa for final destination in Zambia.

Loading of the mining equipment with up to 125 t unitweight was handled by a dockside crane.

Discharging of the converter from vessel onto the trailer in the South-African port was also done by a dockside crane.