Case Studies in USA

SDI Steel Mill project Texas

SDI Steel Mill project Texas

Branch in charge: Germany / Houston

Destination: Sinton,Texas, USA

Cargo: Steel Mill

Volume: 120,000 frt, heaviest piece 125 t

Job description:

Hansa Meyer Global Transport Bremen had been nominated to deliver cargo by break bulk and container vessel ex Europe and Asia for a steel mill project up to jobsite Sinton Tx USA.

Beside the sea-transport by container and break bulk vessel, the project includes foundation placement of critical units by using Hansa Meyers Heavy Haul & Rigging owned equipment.

The total project has a volume of approximately 120.000 FRT and includes units up to 125 tons piece weight.

Closed-die forging Press

Closed-die forging Press

Branch in charge: Germany

Destination: Long Beach, CA, USA

Cargo: Closed-die forging Press

Volume: 10,000 frt, heaviest piece 310 t

Job description:

Hansa Meyer Global Transport Bremen had been nominated to deliver cargo by break bulk and container vessel for a “Closed-die forging press” up to CFR Los Angeles.

Beside the sea-transport by container and break bulk vessel, the project includes pre-carriage by coaster to North Sea ports on the mainland and trucking from inland location in Germany and Italy.

The total project has a volume of approximately 8.000 FRT and includes units up to 320 tons piece weight.

Stacker – Reclaimer

Stacker – Reclaimer

Branch in charge: Germany

Destination: Burns Harbor, (IN), USA

Cargo: Reclaimer

Volume: 13,000 frt, heaviest piece 172 t – 22 m height

Job description:

Our scope of work comprised all services from FOT Germany and FOB Shanghai, China up to DAP Burns Harbor, Indiana, USA. Shipments arrived by charter vessel at consignee´s private pier, where a direct discharge from vessel to truck was arranged for all items. The biggest challenge was the transport of a 172 t unit with a huge height of 22 m.

GNL del Plata Project, Uruguay

GNL del Plata Project, Uruguay

Branch in charge: Brazil

Destination: Muskegon, (MI), USA

Cargo: Jack up Barge, Modular Barges and Constructions for onshore infrastructure

Volume: 116 units / abt 6.000 frt / 1.275 t incl. 4 units each 30.5 m length / abt 26 t unitweight

Job description:

Hansa Meyer Global has been awarded to handle Port to Door services, for the return of a dismantled Jack Up Barge, modular barges and constructions for onshore infrastructure of the LNG Terminal. Cargo loaded on breakbulk vessel from Montevideo, UY to Houston, TX for on carriage by truck to Muskegon, MI.

Oil Rig Move

Oil Rig Move

Branch in charge: USA

Destination: Houston

Cargo: Offshore drilling rigs

Volume: 1.552 cbm / 1.206 t, incl. heavy lifts up to 173 t unitweight

Job description:

Hansa Meyer Global USA has been contracted to move three offshore drilling rigs from the fabrication yard outside of Houston to the port. We also arranged export packing, consolidation and inventory of each of the rigs.

This was the first major project we handled with our sister company’s fleet of trucks.

Rail Move March

Rail Move March

Branch in charge: USA

Destination: Alexandria, (ND), USA

Cargo: Vessels

Volume: 8 Vessels

Job description:

The project consisted of seven vessels discharged in the Port of Houston and one vessel with an origin in Minnesota. Considering the strict deadline, the team developed a rail solution to ensure delivery prior to changes in the local seasonal road regulations. From Houston the seven vessels, were loaded from ship on to seven 8-line rail cars with 70’decks. Using a special train, the transit was six days, well ahead of all deadlines.

An additional vessel that was 135′ long, 330,000 lbs came out of Minnesota. Using Push and Pull trucks equaling 1,300 horse power but executed without delays.

Cement Plant

Cement Plant

Branch in charge: Germany

Destination: Florence, CO, USA

Cargo: Cement Plant

Volume: 4,000 frt

Job description:

Several shipments from Europe and Malaysia to Houston, TX for on-carriage to the site at Florence, Colorado.

Grinding table

710 x 220 cm 135 t

Mill cylinder

1750 x 560 x 570 cm 160 t

Roller units

387 x 222 x 273 cm 84 t

Metal Processing Plant

Metal Processing Plant

Branch in charge: Germany, USA, Mexico and China

Destination: Calvert, AL, USA

Cargo: Metal Processing Plant

Volume: 5,000 t - 21,000 frt

Job description:

Several shipments from Europe, China and Mexico to US Gulf ports of Houston, New Orleans and Mobile including on-carriage to the construction site in Calvert, AL.

Ocean shipments were arranged by conventional liner services and charter vessels.

Transformer

Transformer

Branch in charge: Germany

Destination: Miami, Florida, USA

Cargo: Transformer

Volume: 717 frt

Job description:

Export of 3 transformer 217 t each from Austria via Antwerp, Belgium to Wellington and Miami, USA.

On-carriage from West Palm Beach to the sub-stations was handled on twofold wider Goldhofer trailers.

The transformers arrived at the sub-stations and were placed on the foundation by means of a jack and slide method.

The whole project was carried out in cooperation with Hansa Meyer Global Transport USA.

Gearbox

Gearbox

Branch in charge: Germany

Destination: Charleston, SC, USA

Cargo: Gearbox and Load Disc

Volume: 465 frt

Job description:

A 310 t gearbox and an additional load disc weighing about 155 t were trucked from Rheine and Osnabruck in Germany to an inland port for shipment by barge to Antwerp (Belgium).

Direct unloading from the barge on board of a container vessel as breakbulk cargo at Antwerp for shipment to Charleston. Upon arrival, discharge onto a private barge for a shuttle to the pier and oncarriage by a low-bed trailer to Clemson, SC.

Metal Processing Plant

Metal Processing Plant

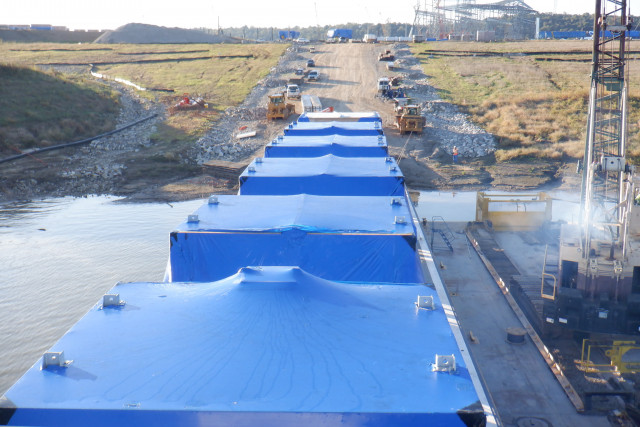

Branch in charge: Bremen

Destination: Brandenburg, KY, USA

Cargo: Steel Plant Equipment

Volume: 20,600 frt

Job description:

Hansa Meyer Global Transport was nominated by SMS group GmbH to ship abt. 20,600 frt equipment for the construction of a new steel plant complex including a continuous slab caster and heat treatment line.

Our scope started at FCA/FOB various European/Asian origins up to DAP Brandenburg KY, USA; including various H/L units with a unit weight between 30 t and 93 t.

The H/L units along with the accessories were shipped in several Lots up to New Orleans, LA from where the goods were taken over to a total of five (5) deck barges for delivery to place of delivery in Brandenburg, KY.

General cargo was mainly shipped to Charleston, SC, Savannah, GA and Baltimore, MD as well as other USEC ports for subsequent truck delivery to site.